AXEL-TECH TEFLON COATING

Protect your Surgical and Dental instruments with ceramic teflon and silicon coatING

we are deal Teflon/ PTFE , ETFE , FEP, silicon, ceramic and high performance nonstick coating for surgical instruments and Die moulds

Ceramic Coating

Ceramic coatings maintain their integrity under high temperatures encountered during sterilization, ensuring instrument safety and longevity.

TEFLON Coating

Teflon coatings, made from polytetrafluoroethylene (PTFE), offer exceptional non-stick properties, reducing friction and enabling smooth operation of surgical instruments.

Silicon Coating

Silicon coatings are biocompatible and inert, minimizing the risk of allergic reactions or tissue irritation in patients.

PROTECT YOUR INSTRUMENTS

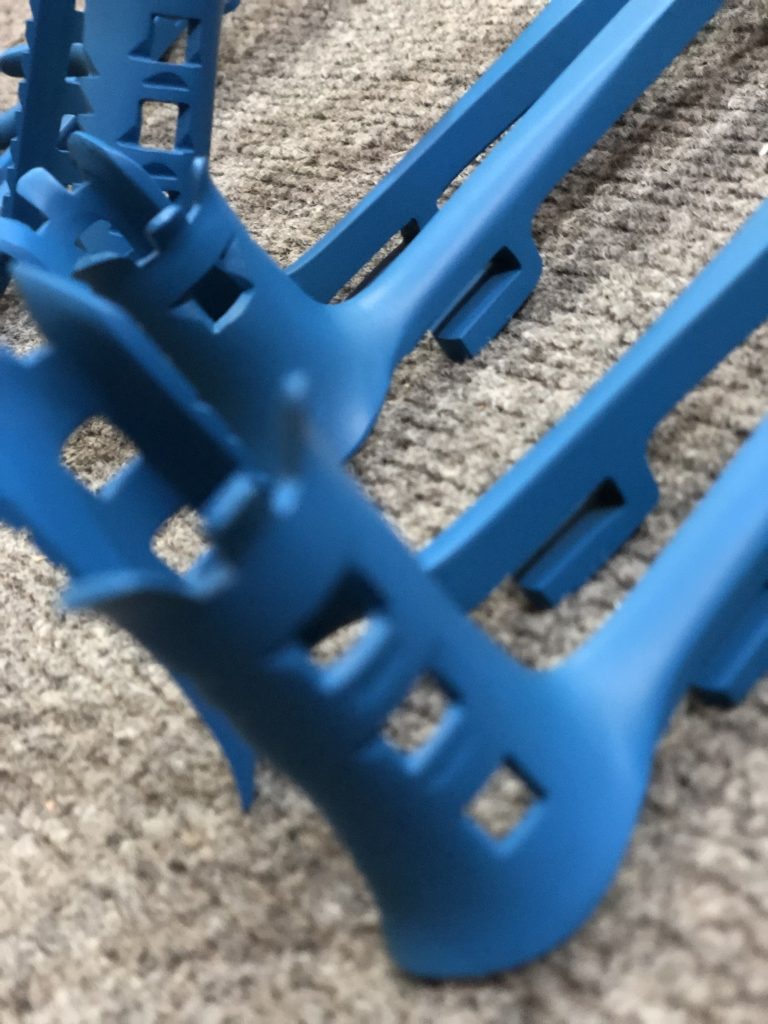

Surgical instruments coating involves applying specialized coatings to enhance their performance, durability, and safety

- Reduced Friction

- Improved Lubrication

- Ease of Cleaning:

- Resistance to Corrosion

- High Hardness

- Excellent Thermal Stability

- Soft Tissue Protection

- Chemical Resistance

- Available in all colours

- Ease of Sterilization

Ceramic Teflon And Silicon coatings can be applied to various surgical instruments

- Grasping and Holding Instruments

- Cutting Instruments

- Clamping and Occluding Instruments

- Retracting Instruments

- Suturing and Stapling Instruments

- Aspiration and Irrigation Instruments

- Neurosurgical Instruments

- Ophthalmic Instruments

- Ear, Nose, and Throat (ENT) Instruments

- Cardiovascular Instruments

- Orthopedic Instruments

- Microsurgical Instruments

- Laparoscopic Instruments

- Miscellaneous Instrument

COATED VS NON COATED

top benefits

MEdical COATING

Teflon and Ceramic coatings ensures that they meet quality standards consistently. By verifying properties such as adhesion, thickness, and chemical resistance, testing helps maintain the quality and reliability of coated surgical instruments, reducing the risk of defects or malfunctions during procedures.

YOUR QUESTIONS ANSWERED

Common Questions

How to Apply of Coating:

Dip And Spin Dip the cleaned surgical instruments into the coating solution, ensuring that the entire surface is submerged.

After dipping, the substrate is subjected to a spinning or rotating motion. This spinning action helps to evenly distribute the coating solution across the surface of the surgical instruments,

TEFLON nonstick coating are same for cockwear and Medical

No Both Are different their compositions, properties, and intended uses are quite different. Cookware coatings focus on nonstick properties for cooking convenience, while surgical coatings prioritize factors like safety, compatibility with bodily tissues, and resistance to sterilization methods.

Surgical Coatings: These coatings are used in medical devices and instruments for surgical procedures. They serve various purposes such as reducing friction, preventing corrosion, improving biocompatibility, or providing antimicrobial properties. These coatings are designed to meet strict medical standards for safety, biocompatibility, and durability.

Cookware Coatings (such as Teflon): These coatings are applied to the surfaces of pots, pans, and other cooking utensils to prevent food from sticking during cooking. Teflon is a common material used in cookware coatings due to its nonstick properties, which make cooking and cleaning easier.

These Coatings Are bio compatibility

Yes, exactly. Surgical coatings used on medical devices and instruments are often designed with biocompatibility in mind. Biocompatibility refers to the ability of a material to perform with an appropriate host response in a specific application. In the context of surgical coatings, biocompatibility ensures that the coating does not cause adverse reactions when in contact with living tissues or bodily fluids.

This is Autoclavable

Yes, These surgical coatings are designed to withstand the autoclave process. Autoclave is a common method of sterilizing medical instruments and devices by subjecting them to high-pressure saturated steam at elevated temperatures, typically around 121-134 degrees Celsius (250-273 degrees Fahrenheit), for a specified period of time.

Coatings used on surgical instruments and devices must be able to withstand the harsh conditions of autoclaving without degrading or compromising their performance. Therefore, these coatings are often selected or formulated to be autoclavable, meaning they can maintain their integrity, functionality, and biocompatibility after repeated autoclave cycles.

Ensuring that surgical coatings are autoclavable is crucial for maintaining the sterility and safety of medical instruments and devices used in surgical procedures. It allows healthcare professionals to effectively sterilize and reuse these instruments, reducing the risk of infection and contamination during surgical interventions.

Ceramic Teflon and Silicon coating Are Same

Answer in No

The choice between ceramic, Teflon (PTFE), and silicone coatings often depends on factors such as desired durability, safety concerns, and specific application requirements.

What is Coating Layer Thickness

Coating Thickness is 2 to 4 Microns

Why choose AXEL-TECH Teflon Coating

Expertise: With over a decade of experience, our team boasts unparalleled expertise in coating applications, backed by a deep understanding of materials and processes.

Quality Assurance: We adhere to stringent quality standards throughout our operations, ensuring that every coated product meets or exceeds your expectations.

Custom Solutions: Recognizing that every project is unique, we offer tailored coating solutions to address your specific requirements, delivering results that are precise and reliable.

Certifications

- ISO 13485 Certification

- FDA Approval or Clearance

- ISO 10993 Biocompatibility Testing

- ASTM F136/F138 for Surgical Implants

- Good Manufacturing Practice (GMP)

- NACE Coating Inspector Certification

- DuPont Teflon Certification

- SSPC Coating Application Specialist Certification